Brand: ZHEHAN/ HUANGZHENG

Material : SS 304, 316, 316L

Diameter: 30~120mm, Standard diameter: 45mm or custom

Wedge wire: 1*2mm, 1.5*2.5mm, 2.5*3.5mm,3*4.5mm

Support rod: 1.8*2.5mm, 2.5*3.5mm, 3*4.5mm

Slot size : 0.1~1mm

Interface: Threaded interface or welded interface

Thread: M, NPT, GBS.P, external thread, the internal thread, no thread, etc.

Flow rate: 0.5-3T/h

Description

Quartz sand filters are generally used as pretreatment for reverse osmosis equipment and ultrafiltration equipment, mainly to intercept and adsorb sediment, colloids, metal ions and organic matter.

Application

Quartz sand filters are widely used in agricultural irrigation, chemical industry, petroleum, metallurgy, industrial and mining and other industries.

Introduction

Quartz sand filters are generally used as pretreatment for reverse osmosis equipment and ultrafiltration equipment, mainly to intercept and adsorb sediment, colloids, metal ions and organic matter. Commonly used filter materials include quartz sand, activated carbon, anthracite, manganese sand, etc. Widely used in agricultural irrigation, chemical industry, petroleum, metallurgy, industrial and mining and other industries.

Working principle

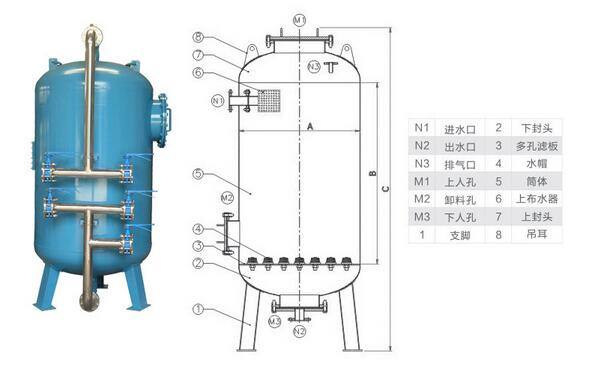

During the filtration process, raw water enters through the water inlet on the upper part of the filter and passes through the quartz sand layer. Due to the large pores and gaps of the quartz sand, impurities such as particulate matter and organic matter in the water can be effectively removed. When the water flows through the filter layer from top to bottom, the suspended matter contained in the water flows into the tiny pores formed by the upper filter material, is adsorbed and mechanically blocked, and is intercepted by the surface layer of the filter material. At the same time, "overlapping" and "bridging" effects occur between these trapped suspended solids, forming a thin film, which continues to produce filtration.

Application of quartz sand filter

The quartz sand filter is a pressure filter that uses refined quartz sand filter material filled in the filter. When the incoming water flows through the filter layer from top to bottom, the suspended solids and viscose particles in the water are removed, thus Reduce the turbidity of water.

It is mainly used for pre-treatment of turbidity removal, softened water, electrodialysis, and reverse osmosis in water treatment. It can also be used for surface water, groundwater, etc. It can effectively remove suspended solids, organic matter, colloids, sediment, etc. in the water.

After the water is coarsely filtered by quartz sand, it passes through the water filter nozzle for final fine filtration, and finally the clean water flows out from the water outlet. The water filter nozzle is made of wedge wire and welded by surface wire wrapped around support rods. It has strong pressure resistance and a minimum slot of 20 microns for better filtration effect.

Types of water filter nozzles

Water filter nozzles generally come in two types: plastic and stainless steel wedge wire. Huanzheng produces high-quality stainless steel wedge-shaped wire water filter nozzles. There is detail introduction of filter nozzles in our web: https://www.zhehanfilter.com/water%20treatment%20filter/filter-nozzle.html

The advantage of wedge wire screen

1. The continuous slot greatly increases the water passage area, so it has better contact with the aquifer.

2. The V-wire section structure avoids blockage and ensures smooth circulation.

3. Continuous slot can be used effectively for a long time.

4. The trapezoidal wire water filter pipe has firm structure, high porosity and precise slot size.

5. The trapezoidal wire water filter pipe is easy to backwash, has a long service life, is safe and reliable, and has low comprehensive cost

1. All of our wires have undergone annealing treatment, which enhances their tensile strength and allows them to withstand greater pressure while ensuring hardness and adapting to more demanding working environments. Other manufacturers use ordinary steel wire, which is directly rolled into wire and lacks sufficient tensile strength and hardness, making it not durable.

2. Our wire goes through 6 processes: flattening, rolling, annealing, drawing, etc., with a tensile strength of about 25, while other manufacturers generally have a strength of 1-7, which is easy to break and has weak pressure bearing filter nozzleacity.

3. We have specially designed a mold to make the roundness of the filter element close to that of a pure circle, with stronger adaptability, easier welding, and no residual impurities. Other manufacturers do not have similar designs, and the cross-section of the filter element is polygonal. It is impossible to fully weld the joint during welding, which can cause blockage and residual impurities in the filter element during use.

4. We use wire cutting machine to reduce the residue generated during cutting, and make sure the size is correct and improve the precision.

Other manufacturers directly use cutting machines to cut, but the burrs cannot be thoroughly treated, and stainless steel slag will fall off during use, affecting subsequent equipment.

5. For threads, we use a lathe to make connector such as threads and tri-clamp, which have more precise dimensions, smooth surfaces, and are easy to use.

Other factories:the connector made by the thread rolling machine has a rough surface, imprecise dimensions, and is difficult to install.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved